Our Partners

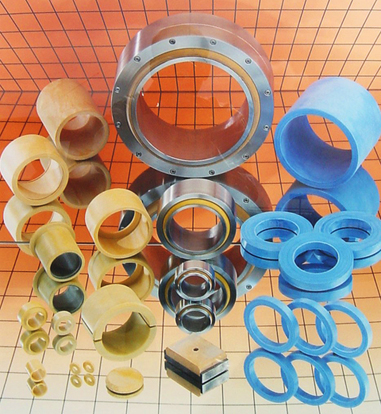

D-Glide Bearing Solutions

The D-glide family is a series of modern composite bearing materials that all consist of a combination of modern synthetic fibres and resins.They are being produced according to the latest technology. The D-glide P. F and FC qualities contain, amongst other ingredients, PTFE.This has resulted in friction values for these materials that are on an unequalled low level, compared with other plastic bearing materials as well as with respect to conventional lubricated plain bearings. Also the 'stick-slip' behaviour, for practical applications a very important property, is better than of other plain bearings.

A major advantage of composite bearings in general, is that they in most cases do not need lubrication, this usually means though, that concessions need to be made to the lifetime. However, not with 0-glide. Depending on the application, increases in lifetime compared with, for example, 'bearing bronze' of 2 to 10 times are feasible. an>Lubrication also does not have a bad influence and not only oils and greases, but almost all non-abrasive media can act as lubricant 0-glide P and F do not guide electricity which means that in corrosive environments corrosion of shafts and other surrounding melzi parts is being prevented. Because the materials are virtually inert, reactions with for example, food and cleaning substances almost never occur. Absorption of water and other fluids is negligible.

By using the latest generation of synthetic fibres, resins and additives, this results in D-glide bearings that can operate In most applications without any form of maintenance, Bearings that allow the highest loads, with low to ultra-low wear rates and friction values_ Bearings that are resistant to almost everything, Immersed In water or dry and anywhere In between and from arctic to tropical conditions. Bearings that are environmentally friendly, both in production and use.

Main Properties of D-Glide Bearings

|

|

|

|

|

|

|

|

|

|

||

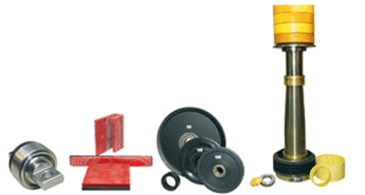

Brake And Clutch Solutions

The role of DRIE-D with respect to the brake linings is twofold. We supply our own brand of asbestos free woven brake lining and we represent some of the world's leading friction material manufacturers. DRIE-D for example represents the Honeywell Allied Signal subsidiary JURID for their industry and railway brake linings. We hold an extensive stock of sheet and roll material in all sizes and of finished blocks and facings for many popular brake and clutch brands. This enables us to ship 99 percent of our orders the same day.

Besides this we have one of the most modern friction repair shops in the country where all brake related work is being carried. Our large oven is big enough to vulcanize all linings that normally are vulcanized.

We also rivet or bolt brake linings to their backings if there are good reasons to do so and if customers prefer to do this themselves we can also provide the special bolts or rivets.

With our machining equipment we can make frictions rings in all current diameters and we are very good at refurbishing friction cones.

Port Equipment Solutions

Reduction of maintenance and down time always was and always will be amajor goal for any port operation. Components break down because of design flaws, insufficient lubrications, less than optimum material choice or simply because the conditions and usage are more severe than foreseen. DRIE-D cannot change operating conditions but everything else falls within our area of expertise.